1884 - Sveriges första lampfabrik

Sjöfararfamiljen Skantze har sedan århundraden haft sitt huvudsäte i områdena kring halländska Kungsbacka. Därifrån har man i generation efter generation fört ut sina fartyg på valjakt, fiske och handel - långt ut på världens hav.

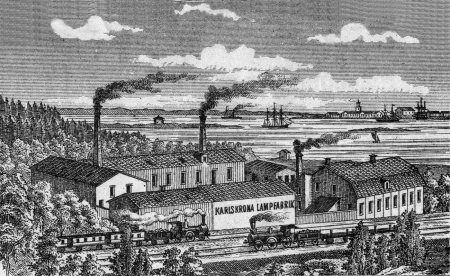

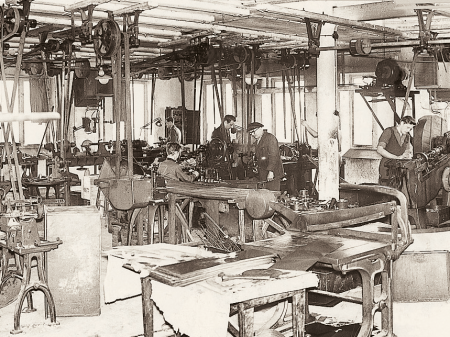

I mitten av 1800-talet sätter den svenska industrialiseringen fart - fabriker startas runt om i Sverige och för detta krävs driftiga män med ledaregenskaper. Många av dessa kommer från befälsleden i den svenska sjöfarten - en av dem är Sjökaptenen Herman Skantze som tillsammans med sin kusin C.A Swahn beger sig till Örlogsstaden Karlskrona för att där grunda Sveriges första fotogenlampfabrik. De ser en stor marknadspotential i den nya tekniken, inte minst hos den svenska flottan och den expanderande järnvägen.1893 - Utveckling och expansion

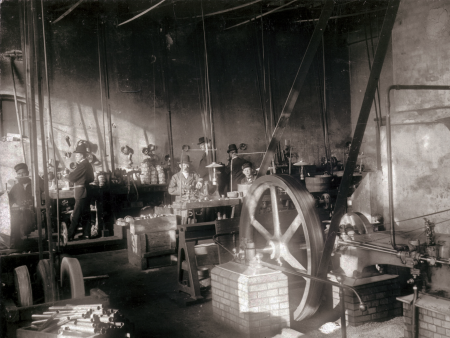

Fotogenbrännaren är en avancerad produkt, med många små detaljer som skall tillverkas och sättas samman - detta kräver kunnande och kapital. Kapitalet kommer från CA Swahns farbror - den framgångsrike klädesfabrikören Johannes Swahn. Kunnandet kommer från Tyskland -som med sitt preussiska skolväsende skapat en kader av exempellöst skickliga ingenjörer, och lagt grunden för det som snart kommer att bli världens främsta industrination. Som tysk konsul i Karlskrona har C.A Swahn de rätta kontakterna och med tysk hjälp och tyska maskiner, expanderar fabriken 1893 till nybyggda lokaler inne i centrala Karlskrona.1897 - Prisbelönta fotogenlampor

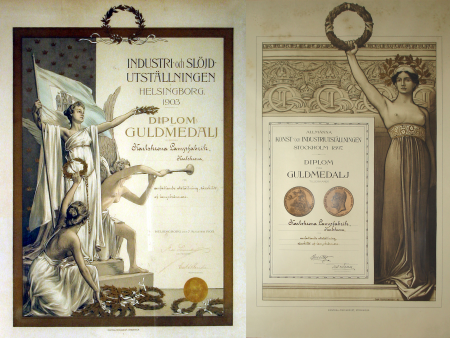

Med en årlig tillverkning på närmare en halv miljon brännare, och över 500 katalogförda modeller, samt en bred tillverkning av specialarmaturer för elektricitet och gas, är Karlskrona Lampfabrik den ledande aktör inom belysningsområdet i södra Sverige. Som ett yttersta bevis på produkternas höga kvalitet tilldelas fabriken första pris och guldmedalj vid den stora industriutställningen i Stockholm 1897, samt ytterligare medaljer vid utställningarna i Helsingborg 1902 och Karlskrona 1903.1914 - Världskrig och regression

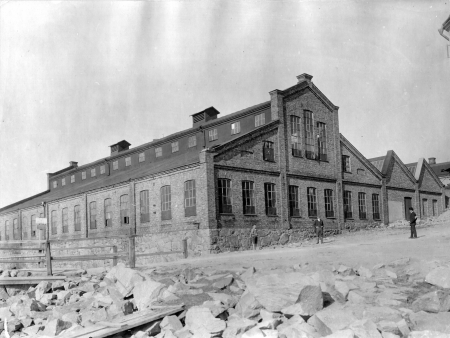

1899 tar Hugo Skantze över som andra generationens Lampfabrikör och verksamheten tar en ny inriktning. Han satsar allt mer på den nya elektriska belysningstekniken, inte endast vad gäller tillverkning av armaturerna, utan med sikte på att bli en av de ledande aktörerna i elektrifieringen av södra Sverige. Han köper ny industrimark på Pantarholmen, där ett stort gjuteri med mekanisk verkstad uppförs. Här tillverkas gjutna lampdelar och lyktstolpar, men även mycket av den kabelgarnityr som behövs för installationsverksamheten.

1914 inleds kriget som kommer att bli en europeisk katastrof som även Lampfabriken dras med i. Oljeransoneringen gör att fotogenlamporna blir oanvändbara och som över en natt försvinner marknaden för dessa produkter nästan helt. Vid krigsslutet insjuknar Hugo och dör, samtidigt som sönerna ännu är för unga för att kunna ta över.1933 - En ny generation tar vid

Äldste sonen, Lars-Olof Skantze, är utbildad elektronikingenjör och har erfarenheter som chef för SKF i Latinamerika, när han 1933 tar över som fabrikör. Hans plan är att rationalisera och få upp lönsamheten och han säljer därför fabriksfastigheten i centrala Karlskrona för att koncentrera hela verksamheten till det ombyggda gjuteriet på Pantarholmen - där vi sedan dessa har bedrivit vår verksamhet.

Fotogenlamporna för en tynande tillvaro, och man satsar istället helt ut på den elektriska belysningen. Man moderniserar delvis sortimentet, men behåller även de klassiska modellerna från det sena 1800-talet, som än idag utgör Lampfabrikens signum.1950 - Traditionellt hantverk i en modern tid

När Lars-Olof väljer en politisk karriär tar hans yngre bror Björn-Orvar över som fabrikör. Hans roll blir att förvalta hantverkskunnandet i ett samhälle präglat av snabb modernisering och automatisering. Det blir en stor utmaning, då industrin i övrigt skiftar fokus från småskalig tillverkning av högkvalitativa produkter mot en kostnadseffektiv produktion i stora volymer. Familjens konservativa syn på hur tillverkningen bör bedrivas, i kombination med en ovilja att ta in externt kapital, gör att man fortsätter med den hantverksmässiga tillverkningen i de gamla tyska maskinerna från Swahns tid.1975 - De svåra åren

Björn-Orvar avlider och sönerna Patrik & Johan Skantze tar över verksamheten. Modernismens syn på formgivning och produktion har nu tagit över helt och kundernas intresse för klassisk formgivning och kvalitet blir allt mindre, till förmån för rationellt producerade lampor i billiga material. Svårigheterna eskalerar ytterligare under 1990-talet när de asiatiska låglöneländerna tar steget in på marknaden. Nästan alla småskaliga fabriker för heminredning i Sverige och Europa läggs ner eller görs om till rena importfirmor. Karlskrona Lampfabrik fortsätter dock på i en mycket begränsad skala att producera sina klassiska mässingsarmaturer för en liten och sparsmakad kundkrets.2006 - Femte generationen tar vid

Patriks son Valdemar Skantze tar tillsammans med sin hustru Katarina över fabriken med föresatsen att ytterligare höja kvalitén på produkterna och lyfta fram det rika historiska arv som företaget besitter och numera är tämligen ensamma om. Ambitionen är att hitta en mer kvalitetsmedveten publik som vet att uppskatta ett genuint svenskt hantverk. Den nya inriktningen visar sig ligga rätt i tiden - i en globaliserad värld där överkonsumtion och långa transporter blir allt mer etiskt oförsvarbart, börjar medvetna kunder efterfråga nationellt särpräglade produkter med en historia och en kvalitet som håller över tid.2024 - En renässans för svenskt hantverk

Karlskrona Lampfabrik är nu inne på sitt 140:e verksamhetsår och efterfrågan på svensktillverkat kvalitetshantverk är större än någonsin. Man tillverkar nu inte endast sina egna lampor, utan även åt andra svenska varumärken, där framförallt Svenskt Tenns lampor - ritade av Josef Frank på 1930-talet - utgör en viktig del.

Större delen av de vinster som genereras återinvesteras i fabriken på Pantarholmen. Målet är att under hösten 2024 öppna upp för en bredare publik att besöka fabriken Satsningen omfattar en större butik och en utställning över företagets långa historia och under 2025 även en café- och restaurangverksamhet.